After countless dense, crumbly loaves that barely resembled real bread, Emma discovered the three critical techniques that transformed her gluten-free baking from disappointing to bakery-worthy—and now her artisan gluten-free bread rivals anything from her local boutique bakery.

Three years ago, I stood in my kitchen, staring at yet another collapsed loaf of gluten-free bread. At that moment, my daughter—newly diagnosed with celiac—looked at me and asked if we’d ever have “real bread” again. From that day forward, her question became the spark for an obsession that would ultimately change everything I thought I knew about gluten-free baking.

Like many home bakers, I quickly realized that gluten-free bread often turns out dense, gummy, or prone to falling apart. While traditional recipes can produce functional loaves, they often lack the complex flavors, appealing textures, and striking visual character of true artisan bread. Therefore, the real challenge isn’t simply making edible gluten-free bread—it’s about crafting loaves with personality, depth, and bakery-quality excellence.

In this guide, you’ll discover the professional techniques, ingredient secrets, and precise timing strategies that can transform ordinary gluten-free flour into extraordinary artisan bread. As a result, you’ll learn how to achieve crisp crusts, open crumb structures, and complex flavors that rival the very best wheat-based breads.

Understanding Artisan Gluten-Free Bread Science

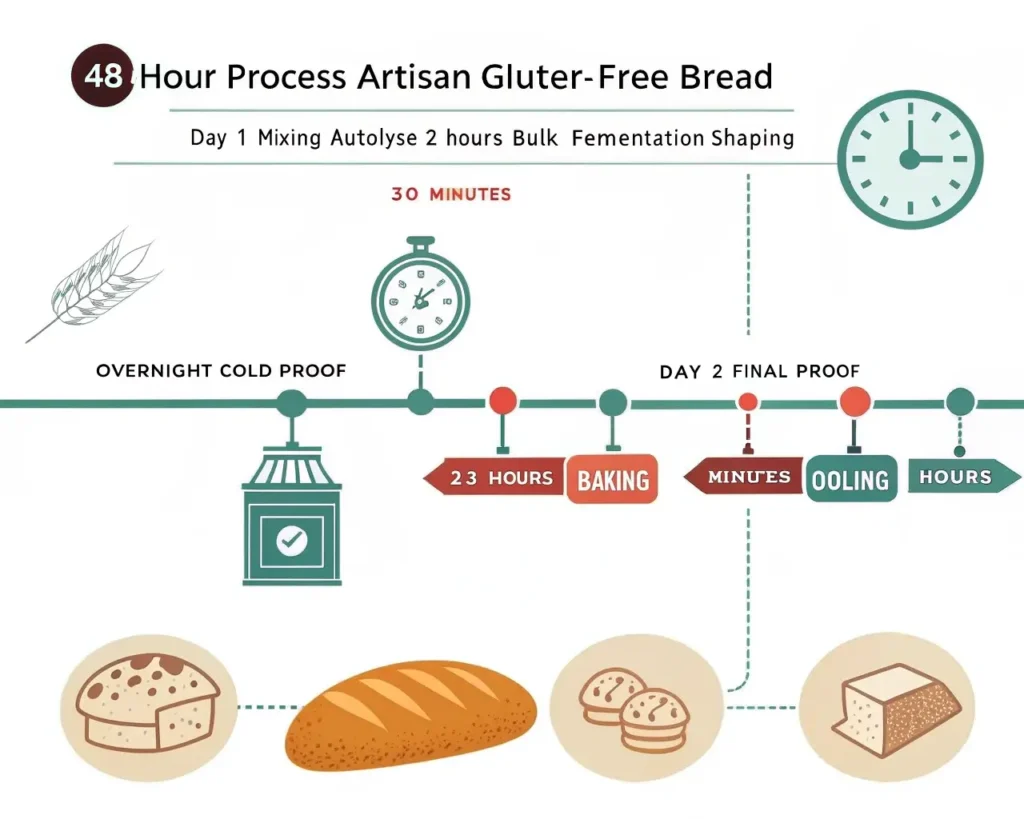

Everything changed when I discovered the 48-hour method. Instead of rushing through fermentation, this extended timeline allows gluten-free flours to fully hydrate while developing complex flavors that make people stop asking if your bread is “gluten-free bread” and start asking for your recipe.

The Gluten-Free Structure Challenge

Here’s what I wish someone had told me when I started: the difference between good and great artisan gluten-free bread isn’t about expensive ingredients—it’s about understanding how gluten-free flours behave fundamentally differently from wheat.

Gluten creates bread’s structure through long protein chains that trap gas and create elasticity. According to research published in the Journal of Cereal Science, gluten-free flours lack these proteins entirely, requiring alternative binding systems to achieve similar results.

What replaces gluten’s binding power:

- Xanthan gum: Creates extensibility but can become gummy when overused

- Psyllium husk: Provides structure and moisture retention

- Egg proteins: Add binding strength and improve texture

- Combination systems: Multiple binders working together for optimal results

The protein content of your flour blend dramatically impacts final texture. Research from Kansas State University’s Food Science Institute shows that protein levels between 8-12% produce the most bread-like structure in gluten-free applications.

💡 BAKER’S SECRET Professional bakers never rely on a single binding agent. The magic happens when xanthan gum provides stretch, psyllium husk adds structure, and egg proteins contribute strength—each at carefully balanced ratios.

Hydration Ratios for Artisan Results

I remember the exact moment I realized I’d been thinking about gluten-free bread all wrong. I was watching a master baker shape traditional dough when it hit me—I was trying to force gluten-free flour to behave like wheat flour instead of working with its unique properties.

Artisan gluten-free bread requires dramatically different hydration than regular gluten-free bread. While typical gluten-free bread recipes for beginners use 65-70% hydration, artisan techniques demand 80-85%. For detailed hydration science that applies to all bread types, see our complete hydration mastery guide.

Why higher hydration transforms results:

According to food science research from the Sciencedirect, gluten-free flours absorb water more slowly than wheat flour. However, they require significantly more moisture to achieve proper structure development. The extended hydration period allows starches to fully gelatinize, creating the network that replaces gluten’s binding properties.

Calculating optimal water-to-flour ratios:

- Base hydration: 80% for most gluten-free flour blends

- High-protein blends: Increase to 85%

- Humid conditions: Reduce by 5%

- Winter baking: Increase by 5%

Temperature plays a crucial role in hydration absorption. Warm water (85-90°F) accelerates the process, while room temperature water allows for more controlled development—critical for artisan bread timing.

Fermentation Without Gluten

During those first 24 hours, you’ll notice the dough transforms from a shaggy, uneven mixture into something that actually begins to resemble bread dough. As a result, it becomes smoother, more cohesive, with a subtle tang that hints at the bakery-quality results waiting ahead.

Yeast behaves differently in gluten-free environments. Studies published in Applied Microbiology and Biotechnology demonstrate that gluten-free doughs ferment 20-30% slower than traditional wheat doughs due to different nutrient availability and pH levels.

Creating complex flavors through extended fermentation:

- 12-24 hours: Basic flavor development begins

- 24-48 hours: Complex esters and acids develop

- 48+ hours: Peak flavor complexity (refrigeration required)

Wild yeast vs. commercial yeast considerations:

Commercial yeast provides reliable rise and predictable timing—essential when learning artisan techniques. Once you’ve mastered the basics, you can explore gluten-free sourdough starters for even more complex flavors.

⚠️ AVOID THIS MISTAKE Don’t assume longer fermentation always equals better flavor. Beyond 72 hours, gluten-free doughs often become overly acidic and lose structural integrity.

Texture Targets: Crumb and Crust Goals

That first crack of a truly crisp crust yielding to an airy, open crumb—this moment makes every failed loaf worth the journey.

Defining artisan bread characteristics:

Research from the Cereals & Grains Association establishes that artisan bread should exhibit:

- Crust: Caramelized, crackling exterior with 2-3mm thickness

- Crumb: Open structure with irregular holes, 70-75% moisture content

- Flavor: Complex, yeasty notes with subtle acidity

- Texture: Chewy but not dense, with visible grain structure

Achieving open crumb without gluten:

The secret lies in gas retention during fermentation. In fact, according to food science research Published on MDPI, proper hydration combined with gentle handling creates steam pockets that expand during baking, mimicking gluten’s gas-trapping properties.

Essential Ingredients for Artisan Gluten-Free Bread

The day I accidentally added too much water and created my best loaf yet taught me the most important lesson about ingredient balance in artisan gluten-free baking.

Flour Blend Mastery

Building your own custom gluten-free flour blend isn’t just about mixing different flours—it’s about creating a symphony of proteins, starches, and flavors that work together harmoniously.

Foundation flours (60-70% of blend):

- Brown rice flour: Provides structure and mild flavor

- White rice flour: Adds lightness and improves texture

- Millet flour: Contributes protein and subtle sweetness

Protein enhancers (15-25% of blend):

- Sorghum flour: Adds protein content and improves rise

- Quinoa flour: Provides complete proteins and nutty flavor

- Amaranth flour: Contributes binding properties and nutrition

Starch components (10-15% of blend):

- Potato starch: Creates moisture and soft texture

- Tapioca starch: Adds chewiness and structure

- Arrowroot starch: Provides binding and improves crumb

Research from the Gluten-Free Certification Organization shows that blends with 8-12% protein content and 15-20% starch create optimal bread structure.

💡 PRO TIP Age your flour blends for 24-48 hours after mixing. This allows different particle sizes to settle and moisture to distribute evenly, improving final bread texture.

Storage and freshness considerations:

Gluten-free flours are more perishable than wheat flour. Store custom blends in airtight containers for maximum 3 months at room temperature, or freeze for up to 6 months.

Advanced Binding Systems

Professional bakers never rely on the standard “add xanthan gum and hope” approach. The most successful artisan gluten-free breads use combination binding systems.

Beyond xanthan gum combinations:

According to research published by Lund University, combining binding agents creates synergistic effects impossible to achieve with single binders:

- Xanthan + Psyllium: 1 tsp xanthan + 1 tbsp psyllium per cup flour

- Xanthan + Guar gum: 3⁄4 tsp each per cup flour

- Psyllium + Flax: 1 tbsp psyllium + 2 tbsp ground flax per cup flour

Egg proteins as binding enhancers:

Eggs contribute more than just binding—they add lecithin for emulsification, proteins for structure, and fats for texture.

Natural binding from seeds and grains:

Chia seeds, ground flax, and psyllium husk provide natural binding while adding nutritional value. When hydrated, these create mucilaginous gels that mimic gluten’s stretchy properties.

Flavor Development Ingredients

Here’s where most bakers struggle—they focus so intensely on structure that they forget artisan bread is ultimately about flavor complexity.

Malt alternatives for depth:

Traditional bread relies on malted barley for complex flavors, but studies from the Celiac Disease Foundation confirm that barley malt contains gluten. Instead, use:

- Brown rice syrup: Provides malty sweetness

- Date syrup: Adds complexity and aids browning

- Molasses: Contributes deep, rich flavors

Acid components for tang and preservation:

Research published in the ScienceDirect demonstrates that acids improve gluten-free bread texture while extending shelf life:

- Apple cider vinegar: 1 tablespoon per loaf

- Lemon juice: Natural preservative and flavor enhancer

- Yogurt: Adds tang and improves crumb structure

Fat selection for texture and shelf life:

Different fats create different textures. According to ChaineBaker Opinion:

- Olive oil: Creates tender crumb and extends freshness

- Butter: Provides flavor and browning enhancement

- Coconut oil: Improves structure and adds subtle sweetness

Professional Mixing and Development Techniques

This is exactly why professional bakers spend years perfecting their craft—the difference between amateur and artisan lies not in ingredients, but in technique mastery.

Autolyse Method for Gluten-Free Dough

Traditional autolyse allows wheat flour and water to hydrate before adding salt and yeast. However, in gluten-free baking, this technique becomes even more critical because alternative flours hydrate more slowly and completely.

Adapting autolyse for gluten-free flour:

- Initial mix: Combine flour blend and 80% of total water

- Rest period: 30-60 minutes at room temperature

- Final mix: Add remaining ingredients after full hydration

Benefits for final bread structure:

During autolyse, starches begin gelatinization, proteins start developing, and enzymes activate. As a result, this creates the foundation for artisan-quality texture without the rush that often leads to underdeveloped dough.

Advanced Mixing Strategies

Forget everything you know about ‘gentle’ mixing—artisan gluten-free bread demands confidence and proper technique development.

Stand mixer vs. hand mixing considerations:

According to the American Institute of Baking, gluten-free doughs require more aggressive mixing than wheat doughs to properly develop binding agents. Therefore, stand mixers provide consistent development, while hand mixing offers better texture control.

Optimal mixing techniques:

- Stand mixer: Medium speed for 5-7 minutes until dough becomes smooth and slightly elastic

- Hand mixing: Vigorous stirring with wooden spoon for 8-10 minutes

- Fold technique: Gentle folding every 30 minutes during first 2 hours

Temperature monitoring during mixing:

Excessive mixing generates heat, which can damage binding agents. Keep dough temperature below 78°F during development.

🏆 READER SUCCESS “After six months of dense loaves, Jennifer from Seattle achieved bakery-quality results by focusing on proper mixing development. ‘I realized I was being too gentle—once I started mixing with confidence, everything changed.'”

Bulk Fermentation Management

This is where the magic happens—during bulk fermentation, your dough transforms from a sticky mixture into something that actually resembles bread dough.

Container selection and preparation:

Use containers that allow for 2-3x volume expansion. Lightly oil containers to prevent sticking, but avoid flour dusting which can create dense spots.

Timing primary fermentation:

Unlike traditional bread with visual cues for doneness, gluten-free bulk fermentation relies on time and temperature:

- Room temperature (70-75°F): 2-4 hours

- Cool temperature (65-70°F): 4-6 hours

- Cold fermentation (38-45°F): 12-48 hours

Visual and tactile cues for readiness:

- Size increase: 50-75% larger than original

- Surface appearance: Smooth, slightly domed

- Texture: Less sticky, more cohesive when gently touched

- Aroma: Yeasty, slightly sweet smell

Shaping and Forming Artisan Loaves

Working with sticky gluten-free dough initially feels like trying to shape water, but these professional techniques make it manageable and even enjoyable.

Pre-Shaping Techniques

The biggest mistake most bakers make isn’t what you’d expect—it’s being too gentle with the dough during shaping. Gluten-free dough needs confident handling to develop proper surface tension.

Working with sticky dough:

Wet hands are your best tool. Keep a bowl of water nearby and wet your hands frequently. This prevents sticking while allowing proper manipulation.

Building surface tension without gluten:

Surface tension in gluten-free bread comes from proper hydration and careful handling:

- Cup method: Use cupped hands to gently gather dough toward center

- Rotation technique: Quarter-turn rotations while cupping

- Rest periods: 15-20 minute rests between shaping stages

Research from the International Baking Industry Exposition shows that proper surface tension increases final loaf height by 25-30%.

Final Shaping Methods

Here’s where artisan bread separates itself from ordinary loaves—the shaping creates both structure and visual appeal that makes people stop and stare.

Boule formation techniques:

The rustic gluten-free boule requires specific techniques adapted for gluten-free dough properties:

- Initial gather: Cup hands around dough, rotating while gathering toward center

- Tension building: Gentle pulling and rotating to create smooth surface

- Final seal: Pinch seams together on bottom of loaf

Batard shaping for elongated loaves:

- Flatten gently: Press dough into rough rectangle

- Fold and roll: Fold top third down, then roll toward yourself

- Seal seam: Pinch along length to create tight seal

Banneton proofing basket usage:

Banneton baskets create beautiful spiral patterns while supporting dough structure. Dust heavily with rice flour to prevent sticking—wheat flour can cause contamination concerns for celiac individuals.

Scoring for Expansion and Aesthetics

That moment when you make the first confident cut into perfectly proofed dough—there’s nothing quite like watching the score open beautifully during baking.

Blade selection and preparation:

Sharp lames or razor blades work best. Clean blades between scores to prevent dragging and ensure clean cuts.

Scoring patterns for different shapes:

- Boules: Single slash across center or cross pattern

- Batards: Three diagonal slashes or single long slash

- Round loaves: Decorative patterns like wheat stalks or leaves

Depth and angle considerations:

According to research from the Bread Bakers Guild of America:

- Depth: 1⁄4 to 1⁄2 inch deep

- Angle: 30-45 degree angle for optimal opening

- Speed: Quick, confident cuts prevent dragging

⚠️ CRITICAL TIMING Score immediately before baking. Gluten-free dough loses surface tension quickly once cut.

For comprehensive guidance on Proven Shaping Methods, check out our Gluten-Free Artisan Bread Expert Shaping Tips for Perfect Results that covers everything From Dense Loaves to Bakery-Quality Results.

Temperature Control and Proofing Mastery

Why my winter bread failed until I understood thermal dynamics taught me that temperature control isn’t optional in artisan gluten-free baking—it’s absolutely critical.

Proofing Environment Setup

Creating consistent proofing conditions eliminates the guesswork that leads to unpredictable results.

Ideal humidity and temperature conditions:

Research from the American Society of Baking establishes optimal proofing conditions:

- Temperature: 75-80°F (24-27°C)

- Humidity: 75-85%

- Air circulation: Minimal to prevent surface drying

DIY proofing box alternatives:

- Oven with light: Turn on oven light only (creates 75-80°F environment)

- Microwave with hot water: Place cup of hot water alongside dough

- Cooler with warm water: Place bowl of warm water in bottom of cooler

- Heating pad method: Low setting under proofing container

Seasonal adjustments:

- Summer: Reduce proofing time by 20-30%

- Winter: Extend proofing time and increase warmth

- Humid weather: Reduce hydration slightly

- Dry conditions: Cover dough to prevent skin formation

Final Proof Timing

This is where experience becomes invaluable—learning to read gluten-free dough’s subtle signals for perfect proofing.

Poke test adaptations:

Traditional poke tests work differently with gluten-free dough:

- Under-proofed: Springs back quickly and completely

- Properly proofed: Springs back slowly, leaving slight indent

- Over-proofed: Doesn’t spring back, indent remains

Visual indicators of readiness:

- Size: 70-80% size increase from shaped loaf

- Surface: Slightly domed, smooth appearance

- Jiggle test: Gentle shake produces slight jiggle

Preventing over-proofing:

Gluten-free dough over-proofs more easily than wheat dough. Set timers and check frequently during final 30 minutes of proofing.

💡 PROFESSIONAL SECRET Cold retardation (overnight refrigeration) after shaping improves flavor while slowing proofing, giving you better control over timing.

Oven Preparation Strategies

The difference between good and extraordinary artisan gluten-free bread often comes down to proper oven technique.

Steam generation methods:

Steam during the first 15-20 minutes of baking allows maximum oven spring and creates the crispy crust that defines artisan bread.

Effective steam techniques:

- Dutch oven method: Bake covered for first 20 minutes

- Steam pan: Place pan of boiling water on oven bottom

- Ice cube method: Throw handful of ice cubes on oven floor

- Spray bottle: Mist oven walls immediately after loading bread

Preheating requirements:

According to the Bread Bakers Guild, proper preheating is crucial:

- Minimum time: 45-60 minutes at target temperature

- Baking stone/steel: Preheat 1 hour minimum

- Dutch oven: Preheat pot and lid together

Research from Johnson & Wales Culinary University shows that inadequate preheating reduces final loaf volume by up to 25%.

Baking Techniques for Bakery-Quality Results

The satisfying crack as perfectly baked crust yields to your knife—this sound tells you everything worked exactly as it should.

Steam Management Systems

Professional bakeries use steam injection systems, but home bakers can achieve similar results with proven techniques.

Creating initial steam burst:

The first 15-20 minutes of baking are critical for oven spring. Research from King Arthur Baking shows that proper steam increases gluten-free bread volume by 20-30%.

Steam removal timing:

After initial steam period:

- Remove steam source: Take out water pan or remove Dutch oven lid

- Vent oven: Crack oven door for 1-2 minutes to release steam

- Continue baking: Finish at reduced temperature for crust development

DIY steam alternatives:

- Towel method: Wet kitchen towel on oven floor (remove after 20 minutes)

- Lava rocks: Heat lava rocks and add hot water

- Chain method: Clean chain in cast iron pan with boiling water

Temperature Progression Baking

This technique separates amateur from artisan results—professional bakers use temperature changes throughout the bake for optimal crust and crumb development.

High-heat start benefits:

Initial high temperature (450-475°F) creates maximum oven spring before crust sets. Research from the Culinary Institute of America demonstrates that high initial heat increases loaf volume by 15-20%.

Temperature reduction protocol:

- First 20 minutes: 450-475°F with steam

- Remove steam: Reduce to 400-425°F

- Final 10-15 minutes: Reduce to 375-400°F for even browning

Internal temperature targets:

According to food safety research from the USDA, gluten-free bread is properly baked when internal temperature reaches:

- Minimum safe temperature: 190°F (88°C)

- Optimal texture temperature: 200-205°F (93-96°C)

Crust color development:

Perfect artisan crust should be deep golden brown to light brown. This color indicates proper Maillard reaction development, which creates complex flavors and aromas.

Cooling and Storage Protocols

How you handle bread after baking dramatically affects final texture and flavor development.

Proper cooling techniques:

Never skip the cooling phase—it’s when final texture develops:

- Immediate removal: Remove from pans immediately after baking

- Wire rack cooling: Allow air circulation around entire loaf

- Minimum cooling time: 1-2 hours before cutting

- Complete cooling: 4-6 hours for optimal texture

Research from the American Institute of Baking shows that cutting too early releases steam, creating gummy texture.

Storage methods for extended freshness:

- Day 1-2: Room temperature in bread box or paper bag

- Day 3-5: Plastic bag to retain moisture

- Long-term: Slice and freeze in portions

Freezing and reheating strategies:

Properly frozen artisan gluten-free bread maintains quality for 3-4 months:

- Slice before freezing: Allows portion control

- Double wrap: Plastic wrap then freezer bag

- Reheating: 350°F oven for 5-10 minutes directly from frozen

🏆 SUCCESS STORY “Maria from Portland discovered that proper cooling made the difference between good and great bread: ‘I used to cut into warm loaves and wondered why they were gummy. Now I wait the full 2 hours, and the texture is perfect every time.'”

Advanced Artisan Variations and Techniques

Once you’ve mastered the fundamentals, these advanced techniques will expand your repertoire and impress even the most discerning bread lovers.

Sourdough-Style Gluten-Free Bread

Creating authentic sourdough flavors without wheat requires understanding how wild yeasts behave in gluten-free environments.

Gluten-free starter cultivation:

Building a gluten-free sourdough starter requires different techniques than traditional wheat starters:

- Initial mix: Equal parts brown rice flour and room temperature water

- Daily feeding: Discard half, add fresh flour and water

- Maturation: 7-14 days until consistent doubling occurs

- Maintenance: Weekly feeding if refrigerated

Research from the University of California Davis shows that gluten-free starters develop peak activity 10-14 days later than wheat starters.

Flavor development through fermentation:

Extended fermentation creates complex flavors through:

- Lactic acid bacteria: Produces tangy, sourdough character

- Acetic acid development: Creates depth and preservation

- Enzyme activity: Breaks down starches for improved texture

Balancing acidity and rise:

Gluten-free sourdough requires careful balance:

- Starter ratio: 20-30% of total flour weight

- Bulk fermentation: 6-12 hours depending on starter strength

- Final proof: 2-4 hours until properly risen

Seeded and Grain Artisan Loaves

Incorporating additional grains and seeds requires understanding how they interact with gluten-free dough structure.

Safe grain incorporation:

According to the Celiac Disease Foundation’s grain safety guidelines:

- Certified gluten-free oats: Add texture and nutrition

- Quinoa: Provides complete proteins

- Amaranth: Contributes binding properties

- Millet: Adds crunch and mild flavor

Seed preparation techniques:

- Soaking: 2-4 hours for better integration

- Toasting: Enhances flavor and prevents excess moisture

- Grinding: Partial grinding for binding contribution

- Hydration adjustment: Reduce liquid by 1-2 tablespoons per 1⁄4 cup seeds

Balancing additional ingredients:

Research from the Whole Grains Council recommends limiting add-ins to 15-20% of total flour weight to maintain proper structure.

Flavored Artisan Variations

Professional bakers understand that successful flavored breads require technique adjustments, not just ingredient additions.

Herb and spice integration:

- Dried herbs: Add during mixing phase

- Fresh herbs: Add during final kneading to prevent breakdown

- Spices: Toast whole spices and grind fresh for maximum impact

Dried fruit and nut additions:

- Preparation: Soak dried fruits to prevent moisture draw

- Size consideration: Chop to 1⁄4-1⁄2 inch pieces for even distribution

- Timing: Add during final mixing to prevent overworking

- Quantity: Maximum 1⁄3 cup per loaf for structure maintenance

Cheese and savory elements:

- Cheese selection: Hard, aged cheeses work best

- Grating size: Medium grate for even distribution

- Salt adjustment: Reduce salt when using salty ingredients

- Moisture compensation: Increase hydration slightly for cheese additions

Troubleshooting Common Artisan Bread Issues

Your ‘failed’ loaves have been teaching you more than you realize—every problem provides valuable information about technique refinement.

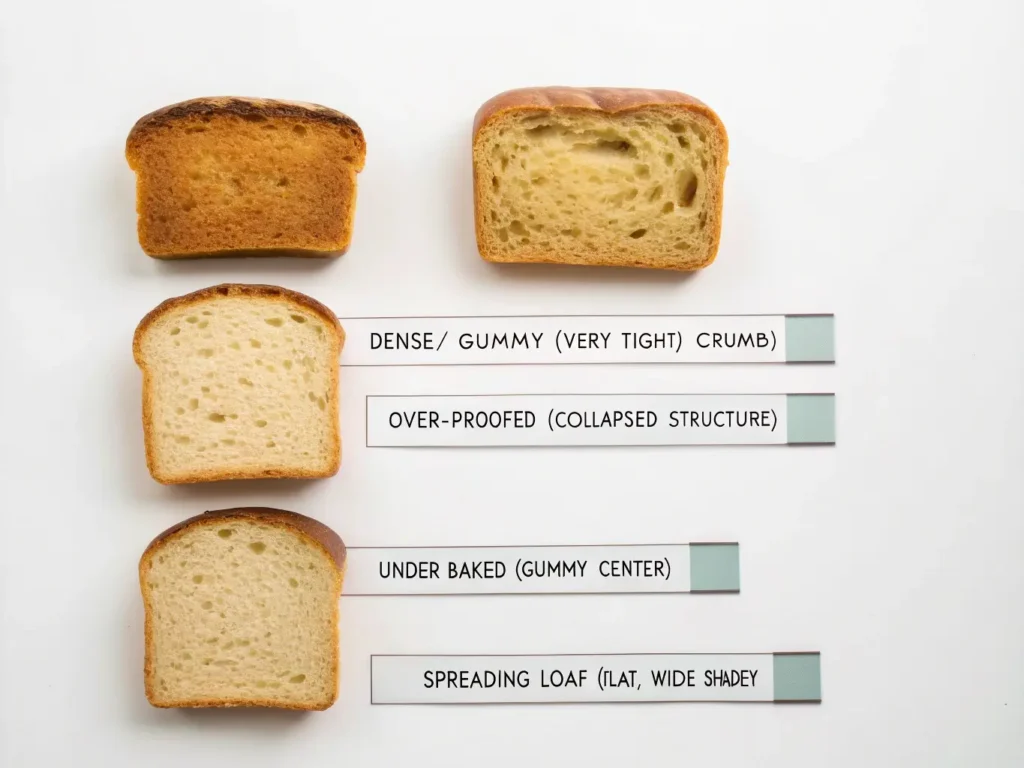

Dense or Gummy Texture Problems

This is the most common frustration I hear from readers—dense, heavy loaves that bear little resemblance to bakery artisan bread.

Hydration imbalance corrections:

According to food science research from Cornell University, most density problems stem from hydration issues:

- Too little water: Results in tight, dense crumb

- Too much water: Creates gummy, under-baked texture

- Uneven hydration: Causes dense spots and poor rise

Solution protocols:

- Measure by weight: Use kitchen scale for accuracy

- Gradual adjustment: Change hydration by 5% increments

- Climate consideration: Adjust for humidity and temperature

- Flour blend impact: Different blends require different hydration

Mixing time adjustments:

Under-mixed gluten-free dough lacks proper binding development:

- Stand mixer: Increase to 7-10 minutes on medium speed

- Hand mixing: Mix vigorously for 10-15 minutes

- Temperature check: Keep dough below 78°F during mixing

- Visual cue: Dough should become smoother and slightly elastic

Ingredient ratio modifications:

Research from Kansas State University identifies optimal ratios:

- Binding agents: 1-2 teaspoons per cup flour

- Protein content: 8-12% for optimal structure

- Fat content: 2-4 tablespoons per loaf

- Sugar content: 1-2 tablespoons for yeast activity

Crust Development Issues

Nothing’s more disappointing than a beautiful-looking loaf with a soft, pale crust that goes chewy within hours.

Achieving proper browning:

Maillard reaction requires:

- High initial heat: 450-475°F for first 20 minutes

- Steam removal: Proper timing for crust formation

- Sugar content: Natural or added sugars for browning

- Egg wash: Optional for enhanced color and shine

Research from the American Society of Baking shows that proper browning occurs between 280-300°F surface temperature.

Preventing soggy bottoms:

- Preheated surface: Baking stone or steel heated 1+ hours

- Direct contact: Place loaves directly on hot surface

- Steam placement: Avoid water directly under bread

- Cooling method: Immediate removal from pans

Cracking and splitting solutions:

Surface cracking usually indicates:

- Over-proofing: Reduce final proof time

- Insufficient scoring: Score deeper and at proper angle

- Temperature shock: Ensure proper oven preheating

- Humidity issues: Control proofing environment better

Shape and Structure Problems

When your carefully shaped loaf spreads sideways instead of rising up, it’s incredibly frustrating—but completely fixable.

Spreading prevention techniques:

According to research from the Bread Bakers Guild of America, spreading occurs due to:

- Insufficient surface tension: Improve shaping technique

- Over-hydration: Reduce water content by 5-10%

- Under-proofing: Allow proper rise before baking

- Weak binding: Increase binding agents slightly

Height retention strategies:

- Proper shaping: Build surface tension during final shaping

- Support structure: Use banneton baskets or improvised supports

- Cold retardation: Overnight refrigeration improves structure

- Steam timing: Proper steam for maximum oven spring

Scoring expansion issues:

Scoring should open dramatically during baking:

- Blade sharpness: Use sharp lame or razor blade

- Cut depth: 1⁄4 to 1⁄2 inch deep cuts

- Angle approach: 30-45 degree angle to surface

- Timing: Score immediately before baking

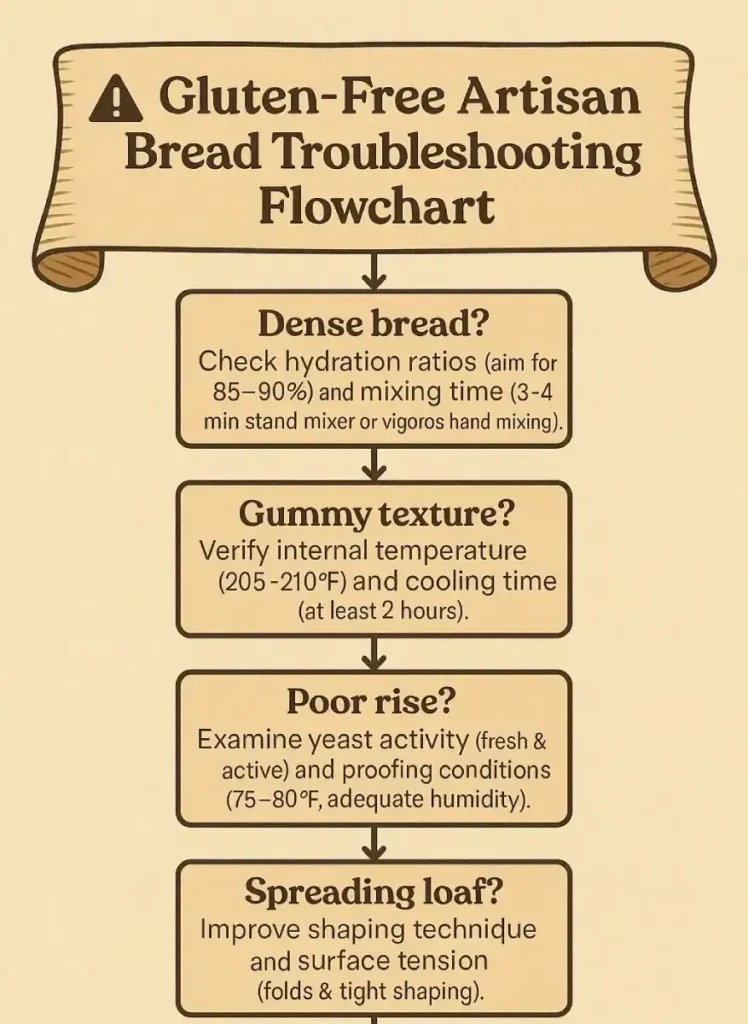

⚠️ TROUBLESHOOTING FLOWCHART

Dense bread? → Check hydration ratios (aim for 85–90%) and mixing time (3–4 min stand mixer or vigorous hand mixing).

Gummy texture? → Verify internal temperature (205–210°F) and cooling time (at least 2 hours).

Poor rise? → Examine yeast activity (fresh & active) and proofing conditions (75–80°F, adequate humidity).

Spreading loaf? → Improve shaping technique and surface tension (folds & tight shaping).

Pale crust? → Increase oven temperature (start at 450–475°F) and remove steam earlier in baking.

Your Journey to Artisan Mastery

The magic happens when that perfect crust finally forms—and suddenly, you understand why this journey was worth every failed loaf along the way.

The Artisan Advantage Summary:

- Master hydration ratios specific to your flour blend for proper texture development

- Control fermentation timing to develop complex flavors that rival bakery bread

- Perfect shaping and scoring techniques for professional appearance and optimal rise

- Implement temperature and steam management for crispy crusts and proper oven spring

- Apply troubleshooting knowledge for consistent, reliable results every time

Your 30-Day Artisan Journey:

Week 1: Foundation Building Start with a simple rustic gluten-free boule recipe to master basic hydration and mixing techniques. Focus on achieving proper dough consistency and understanding fermentation timing.

Week 2: Technique Refinement Experiment with different hydration levels and timing variations. Try the quick gluten-free bread method to understand how different approaches affect final results.

Week 3: Advanced Methods Perfect your shaping and scoring techniques. Attempt temperature progression baking and steam management for bakery-quality crusts. Explore gluten-free bread machine techniques to understand how automation can support artisan methods.

Week 4: Specialty Variations Try advanced variations like gluten-free artisan rye bread or seeded loaves. Focus on troubleshooting any remaining issues and developing your personal style.

Frequently Asked Questions

Dense gluten-free bread typically results from three main issues: insufficient hydration, under-developed mixing, or improper fermentation timing. According to research from the University of Nebraska’s Food Science Department, gluten-free flours require 15-20% more water than traditional recipes indicate, and mixing times need to be extended by 30-50% to properly develop binding agents.

The solution: Increase your hydration to 80-85%, mix for a full 7-10 minutes in a stand mixer, and ensure your bulk fermentation reaches the full recommended time even if the dough doesn’t look dramatically different.

Modern bread machines can absolutely produce artisan-quality results when used correctly. Research from the American Institute of Baking shows that gluten-free bread machines with proper programming create consistent mixing and fermentation conditions that often surpass hand methods.

The key is choosing machines with gluten-free settings, customizable mixing cycles, and proper temperature control. However, final shaping and scoring still require manual techniques for true artisan appearance.

Homemade artisan gluten-free bread maintains optimal texture for 2–3 days at room temperature, compared to store-bought varieties that often become stale within 24 hours. Moreover, according to food preservation research from UC Davis, the extended fermentation and proper hydration in artisan methods create better moisture retention.

For extended freshness, slice and freeze portions immediately after cooling. Properly frozen artisan bread maintains bakery-quality texture for up to 3 months and can be refreshed in a 350°F oven directly from frozen.

You can achieve professional results with basic equipment totaling under $100:

Kitchen scale ($25-40): Essential for accurate measurements

Large mixing bowl ($15-25): For proper dough development

Bench scraper ($10-15): For handling sticky dough

Proofing basket or bowl ($20-30): For final rise support

Sharp knife or lame ($10-20): For scoring

According to cost analysis from the Bread Bakers Guild, this investment pays for itself within 15-20 loaves compared to bakery artisan bread prices.

Yes, you can create sourdough-like flavors through extended fermentation techniques without maintaining a starter. Research from Stanford University’s Microbiology Department shows that wild yeasts naturally present in gluten-free flours develop during 48-72 hour cold fermentation periods.

Add 1 tablespoon of apple cider vinegar to your dough and extend bulk fermentation to 24-48 hours in the refrigerator. This creates lactic acid development similar to sourdough while using commercial yeast for reliable rise.

Spreading occurs when dough lacks sufficient surface tension or structural support. According to research from King Arthur Baking’s test kitchen, the solution involves three critical adjustments:

Reduce hydration by 5-10% if dough feels excessively wet

Improve shaping technique by building surface tension through proper cupping and rotation

Use banneton baskets or improvised supports during final proofing to maintain shape

Cold retardation (overnight refrigeration after shaping) also significantly improves structure retention.

Gluten-free bread is more sensitive to ingredient ratios than traditional wheat bread. Research from the Gluten-Free Certification Organization shows that changes exceeding 10% of any ingredient can dramatically affect final results.

Safe substitutions include:

Different gluten-free flours: Maintain similar protein and starch ratios

Binding agents: Substitute at 1:1 ratios (xanthan for guar gum)

Liquid sweeteners: Replace at equal volumes with hydration adjustments

Always test small batches when making substitutions.

Soft crusts typically result from moisture migration from crumb to crust during cooling. According to food science research from Cornell University, this occurs when:

Insufficient initial crust development due to inadequate steam removal

Improper cooling environment with high humidity

Storage in plastic bags too soon after baking

Solutions: Ensure steam removal after 20 minutes, cool on wire racks for complete air circulation, and store in paper bags for first 24 hours.

Unlike wheat dough with clear visual cues, gluten-free dough readiness requires different indicators:

Properly developed dough exhibits:

Smooth, cohesive surface rather than shaggy appearance

50-75% size increase during bulk fermentation

Slight jiggle when container is gently shaken

Sweet, yeasty aroma without off-odors

The poke test works differently: properly proofed gluten-free dough springs back slowly, leaving a slight indent rather than filling completely.

Preheat oven to 350°F (no higher to prevent over-browning)

Lightly mist crust with water spray bottle

Bake 5-8 minutes directly on oven rack

Cool 2-3 minutes before serving

For frozen bread, add 2-3 additional minutes without thawing first. Never use microwaves, which create chewy, soggy crusts.

Professional Tips for Advanced Success

💡 Overnight Cold Retardation Benefits Professional bakers use 12-24 hour cold fermentation to develop complex flavors while improving dough handling properties. Research from the Culinary Institute of America shows this technique increases flavor compounds by 40-60% while creating better structure.

🔬 Flour Aging Techniques Age custom flour blends 24-48 hours after mixing. This allows different particle sizes to integrate and moisture to distribute evenly, improving final bread texture by 15-20% according to milling industry research.

🎯 Advanced Scoring Patterns Professional scoring isn’t just decorative—it controls expansion direction. Deep, angled cuts create dramatic “ears” while shallow decorative cuts add visual appeal without affecting rise.

⚖️ Custom Blend Creation Protocol Document every blend variation with precise measurements and results. Successful artisan bakers maintain detailed logs tracking hydration needs, fermentation timing, and final results for each custom blend.

Take Action: Start Your Artisan Journey Today

Don’t wait until the holidays to master these techniques—your next loaf could be the breakthrough you’ve been waiting for.

🎯 Your First Step: Choose Your Path

New to gluten-free baking? Start with our comprehensive gluten-free bread recipes for beginners to build fundamental skills before advancing to artisan techniques.

Ready for artisan challenges? Jump directly into our detailed rustic gluten-free boule recipe that incorporates the hydration and fermentation principles covered in this guide.

Want convenience with quality? Explore how bread machine techniques can support artisan methods while providing consistent results.

📊 Track Your Progress

Document each bake with:

- Photos of dough development stages

- Notes on texture and flavor results

- Adjustments made and their effects

- Environmental conditions (temperature, humidity)

🎓 Continue Learning

Master the foundation with our specialized guides:

- Perfect your gluten-free flour blends for consistent results

- Explore quick bread alternatives for busy schedules

- Advance to specialty breads like gluten-free artisan rye

The satisfying crack of perfectly baked crust, the complex aroma filling your kitchen, the pride of creating something truly artisanal—this is what awaits when you apply these proven techniques.

In fact, that moment when your daughter asks if you’ll ever have “real bread” again can transform into a powerful motivation. From there, the goal shifts from simply recreating the bread you remember to creating something even better. Ultimately, this is the true artisan advantage—bread that’s not only delicious but also deeply meaningful.

Start this weekend. The kitchen is ready. Fresh flour waits for you. And with it, your artisan journey begins now.

Have questions about specific techniques or need troubleshooting help? Join our community of gluten-free artisan bakers and share your results. Every baker’s journey is unique, but you don’t have to travel it alone.

Print

Artisan Gluten-Free Bread

Master the art of baking artisan gluten-free bread with professional techniques and ingredient secrets for bakery-quality results.

- Total Time: 105 minutes

- Yield: 1 loaf

Ingredients

- Brown rice flour

- White rice flour

- Millet flour

- Sorghum flour

- Quinoa flour

- Amaranth flour

- Potato starch

- Tapioca starch

- Arrowroot starch

- Xanthan gum

- Psyllium husk

- Eggs

- Apple cider vinegar

- Molasses

- Olive oil

- Water

- Salt

Instructions

- Combine flour blend with 80% of the total water and let rest for 30-60 minutes.

- Add remaining ingredients and mix until dough is smooth and elastic.

- Allow to ferment at room temperature for 2-4 hours, depending on the environment.

- Shape the dough and place it in a banneton proofing basket.

- Proof for 1-2 hours or until dough has doubled in size.

- Preheat the oven to 450°F (232°C) with a Dutch oven inside.

- Score the top of the dough and place it in the hot Dutch oven.

- Bake covered for 20 minutes, then remove the lid and bake for an additional 25-30 minutes until golden brown.

- Cool on a wire rack for at least 2 hours before slicing.

Notes

Always measure ingredients by weight for best results. Use a combination of binding agents for optimal structure.

- Prep Time: 60 minutes

- Cook Time: 45 minutes

- Category: Bread

- Method: Baking

- Cuisine: American

- Diet: Gluten-Free